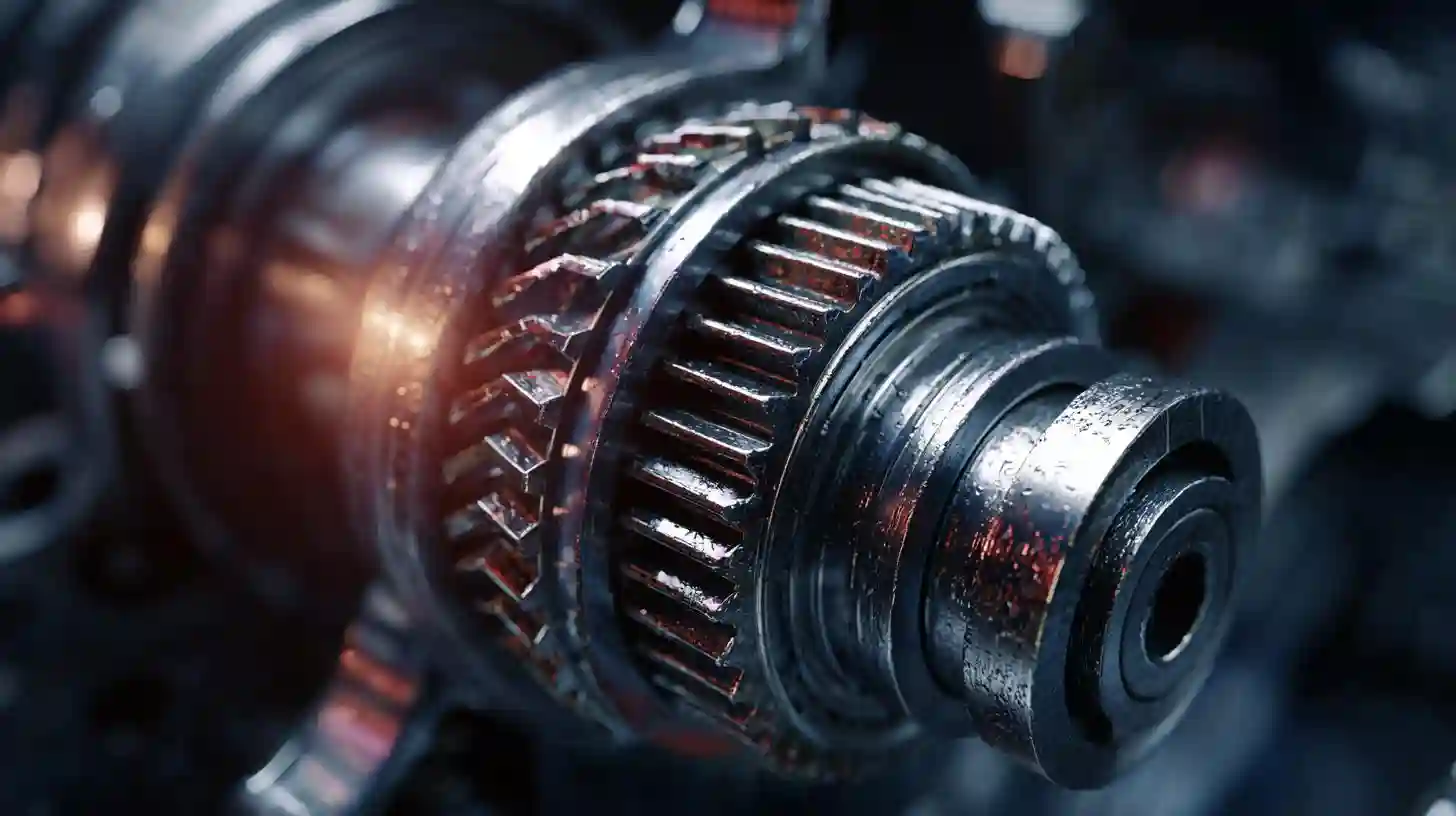

The maintenance and repair of nine-speed gearboxes presents a unique set of challenges for automotive professionals. The intricate design of these transmissions requires a deep understanding of the mechanical systems involved, as well as specialized tools and procedures. With each additional gear, the complexity of the gearbox increases, demanding higher precision in both its operation and its servicing. Each gear interacts with others in specific ways, and even a minor error in assembly or adjustment can cause significant performance issues or even complete failure of the system. This makes the repair of nine-speed gearboxes particularly delicate. One of the most difficult aspects of maintaining these gearboxes is dealing with their high level of technological integration. Many modern nine-speed gearboxes come with electronic components that manage shifting, speed sensors, and even automated systems. These components require specialized diagnostic equipment to identify problems, and traditional mechanical repair methods often fall short. In addition to the electronic aspects, the physical wear on internal parts such as clutches, bearings, and synchronizers presents another challenge. These parts are exposed to intense heat and friction over time, which leads to wear that can impact shifting performance and overall longevity of the gearbox. The intricate nature of the assembly also means that parts are often difficult to access, requiring disassembly of multiple components to reach the problematic area. Once disassembled, reassembly requires precise alignment and torque specifications, as improper reassembly can lead to misalignment, which in turn causes irregular shifting or transmission failure. Another challenge in servicing these gearboxes is their fluid management. Many nine-speed gearboxes rely on specific types of transmission fluid, and using the wrong fluid or failing to replace it regularly can lead to overheating, increased wear, and eventual failure. Proper fluid levels and quality are critical to ensure the longevity and efficient operation of the gearbox. Beyond these technical aspects, the time and cost of repairing a nine-speed gearbox can be prohibitive. Labor costs tend to be higher due to the complexity of the task, and the need for specialized parts can further drive up the expense. As such, proper care and timely maintenance are essential to extending the life of these advanced transmissions. Regular inspections and prompt attention to issues, no matter how small, can help avoid more severe problems down the road.